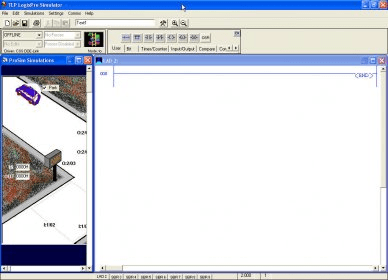

It is possible to come up with a different subroutine arrangement that will work, but at the student level this is not recommended. If you think about the logical steps that must be done in order, then before the elevator can move (Sub 7 Track Car Movement), you must first do Sub 5 (Do Next Request, or Wait). It is best to follow the logic outline given in the LogixPro problem, and not go off on a tangent. The logic must allow for a short stopping time (a LIM range or 2 or 3 encoder counts). The reason is that the elevator can not physically stop immediately when the floor location is sensed. The best method is to use LIM instructions for all 4 floors, so that the stopping point can be a range, not a single encoder value. In Sub 5 (supposed to be 7), the car movement is not tracked correctly. Marcia has got Sub 5 and 7 swapped and mixed up, so that the functions do not work properly. Car Requests 1 and 4 are latched on (correct), other floors 2 and 3 are not. Also, the Car Request buttons are not set up properly. Without those 2 parameters, the elevator will never work correctly. For example, there is no logic to determine the Lowest Floor Requested, or the Highest Floor Requested. In order to add the full functions, much more logic has to be added to Subroutine 4. It was only the LogixPro Elevator Exercise 2 Student Problem, where the elevator is only programmed to go to the 4th floor. (4) by clicking on the data table button a new window will pop up with all the available addresses that you will need.Need your help marcia, could you make the program run? One of the best advantages of this software is the “Drag & Drop” property.Īs you can see in Fig. Available Data Types for LogixPro Software This capability may not be typical of real PLCs, but for Training Purposes, you will find that it is an invaluable debugging tool. Set the scan slow enough and you can easily monitor how your program’s instructions are responding. You can use this to good effect when trying to debug your program. When the simulation is slowed, so is the PLC scanning. This is not a component of normal PLCs but is provided with LogixPro so that you may adjust the speed of the simulations to suit your particular computer. If you take a look at the PLC Panel, you’ll notice an adjustable Speed Control shown in Fig. This will initiate the scanning of your program and the I/O of your chosen simulation. (2) will bring the PLC Panel into view.įrom the PLC Panel, you can download your program to the “PLC” and then place it into the “RUN” mode. Once your program is ready for testing, clicking on the “Toggle Button” of the Edit Panel as shown in Fig. The Edit Panel provides easy access to all the RS Logix instructions and they may be simply dragged and dropped into your program.

0 kommentar(er)

0 kommentar(er)